Newsroom

Swiss Packaging Award 2025 – We are nominated!

Rüthi (St.Gallen) | 5 minutes reading time

Swiss Packaging Award 2025 – Nominated in the Sustainability Category: Our IML‑S+ Twin-Chamber Cup

To be future-ready, you must innovate.

Our IML‑S+ Twin-Chamber Cup has been nominated by the Swiss Packaging Award 2025 jury as a potential winner in the Sustainability category – a clear recognition of packaging that combines intelligent design with functionality and resource efficiency.

Sustainability Meets Innovation

This packaging solution is the result of consistent innovation: based on a skeletal structure, it reduces material usage to a minimum while maintaining full functionality and stability. Combined with In-Mould Labelling (IML), the result is a fully recyclable, monomaterial product with a premium, brand-ready finish.

Key Product Features

Twin-Chamber Design

Two separate compartments allow for the smart combination of products – perfect for snacks with dips, salads with dressings or other on-the-go meals. Clear separation and user convenience are guaranteed.

Skeleton Construction – Less Is More

The structural frame is reduced to what’s absolutely necessary for performance and integrity. The result: significantly less plastic, lighter packaging and lower CO₂ emissions – without compromising product protection.

IML Decoration – Fully Recyclable & Visually Striking

In-Mould Labelling integrates the label into the cup during the moulding process – no adhesives, no extra materials. The benefits:

- 360° print coverage with premium-quality graphics

- Scratch-resistant and long-lasting finish

- Made entirely of a single plastic (e.g., PP) → fully recyclable as a monomaterial

Sustainability Benefits at a Glance

- Reduced Material Use: The skeletal design slashes plastic usage and weight → lower carbon footprint and raw material consumption.

- Recyclable Monomaterial: Label and container are made from the same material – no separation needed, easy to recycle.

- Efficient Manufacturing: IML allows labelling during the moulding process – fewer production steps, less energy consumed.

- Transport & Storage Advantages: Lighter packaging means lower logistics costs and improved environmental impact.

- Premium Brand Impact: IML enables standout packaging designs while supporting your brand’s sustainability message.

What Sets Us Apart

Feature |

IML‑S+ Twin-Chamber Cup |

Material Reduction |

Significant savings thanks to skeleton structure |

Functionality |

Dual compartments for versatile product combos |

Recyclability |

100% recyclable monomaterial |

Aesthetic Appeal |

Premium IML finish with full design freedom |

Production Efficiency |

Fully integrated IML process |

Sustainability |

Visually strong and environmentally conscious |

Packaging That Makes a Statement

The IML‑S+ Twin-Chamber Cup sends a clear message: Design, sustainability and efficiency can go hand in hand. Our nomination for the Swiss Packaging Award 2025 is a fantastic milestone – and a strong motivation to keep pushing the boundaries of packaging innovation.

The winners will be announced on 11 September 2025 – stay tuned!

Change in Our Leadership

Rüthi (St.Gallen) | 3 minutes reading time

Leadership Transition as of February 3, 2025

Rüthi, February 2025 – säntis packaging ag is pleased to announce that, effective February 3, 2025, Michael Thüler will assume the role of Chief Executive Officer (CEO) and Managing Director. After 22 years of dedicated and successful leadership, the current Managing Director, Bettina Fleisch, will transition into the role of Chairwoman of the Board of Directors. In this capacity, she will focus more on strategic matters and the company’s long-term business development.

Michael Thüler holds a degree in Mechanical Engineering from ETH Zurich and an Executive MBA from the University of St. Gallen. He brings extensive experience from various industrial sectors, having held executive positions across different industries. Known for his strong commitment, innovative mindset, and passion for corporate leadership, he is well-equipped to drive säntis packaging ag’s growth and strategic objectives forward.

“We are confident that Michael Thüler will be an excellent addition to our team and will continue to uphold the values of säntis packaging as a family-owned company,” said Bettina Fleisch, owner of säntis packaging ag.

SÄNTIS would like to extend its sincere gratitude to its business partners for their trust and long-standing collaboration. We wish Michael Thüler great success and fulfillment in his new role.

KUB: Lightweight and easy to dispose

Rüthi (St.Gallen) | 2 minutes reading time

Lightweight - beautiful - and naturally recyclable: The new KUB

For 50 years, SwissPrimePack has been a leader in the development and production of high-quality packaging for the dairy industry. Whereas these were previously mainly made of plastic, we are now entering completely new territory. With the production of carton/plastic combinations, we offer a new, forward-looking packaging solution: best recyclability with consistent quality at the highest level.

The KUB is easy to dispose of properly. With a clearly visible tear-off tab, the cardboard is separated from the plastic cup in one easy step. Cardboard comes to cardboard, plastic to plastic. Both materials are thus recycled according to type and optimally recycled.

Our claim is to return 100% of the KUB back into the cycle. The solution for this is offered by the "One-Seal Lid". Made of PP, it replaces the aluminum lid and can be recycled together with the plastic cup. Positive side effect: The cup can be resealed at any time and protects the valuable contents.

As we push for the constant optimization of the circular economy in the interest of sustainable development, we point out another intelligent solution: the digital watermark. Attached to the cup, sleeve or label, this digital symbol, which is not visible to the customer, achieves a great effect. The information stored in it about the packaging material is automatically decoded by a scanner in the sorting system. The packaging is assigned exactly to the correct, unmixed waste stream, resulting in the highest quality recyclates.

Further information about the KUB can be found here.

EnAW Certification 2024

Rüthi (St.Gallen) | 1 minutes reading time

EnAW certification - säntis packaging ag is part of it!

säntis packaging ag has been a participant in the Energy Agency for Industry since 2015 and is thus committed to economic climate protection. Find out more about the commitment and achievements of säntis packaging ag.

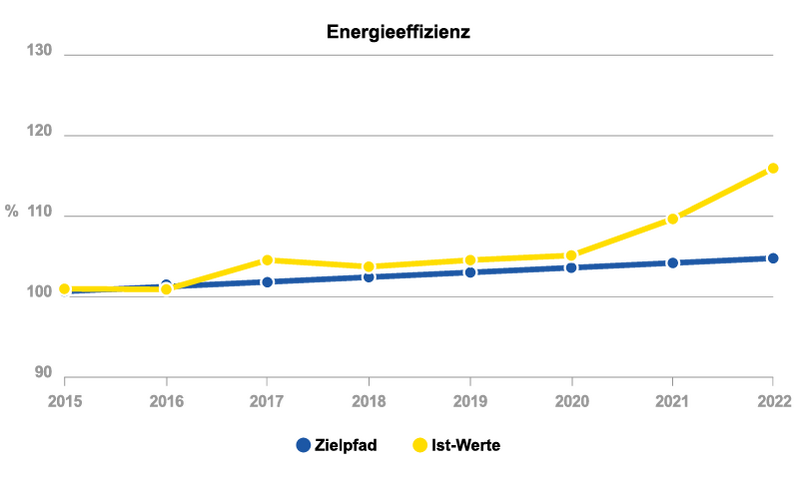

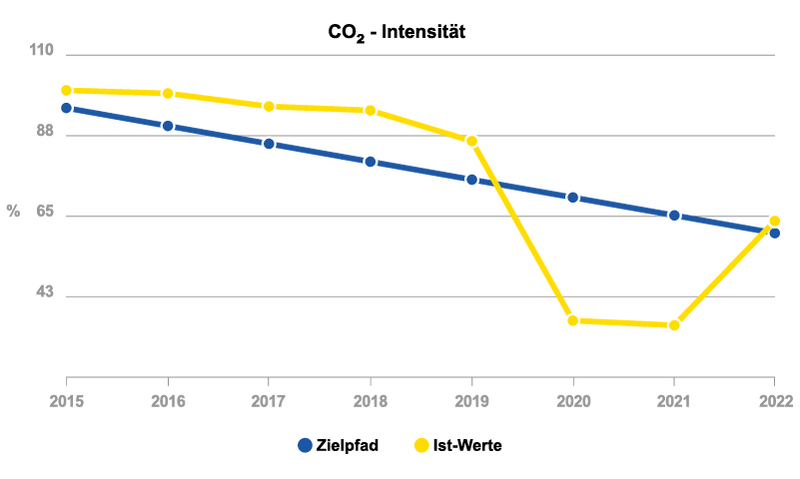

By participating in the energy model, säntis packaging ag has defined energy efficiency targets and CO2 reduction targets in a target agreement. The targets are implemented in a measure-orientated manner over ten years and the achievement of the targets is reviewed annually.

Säntis CEO Bettina Fleisch and Andreas Bolter, Head of Technology, talk about the project in the "Rheintaler" - the largest regional news publication.

Click here for the article in rheintaler.ch

From 2015 to 2022, säntis packaging ag has

saved 3.666 kWh of energy

reduced 124 tonnes of CO₂

Abbildung: Entwicklung der Energieeffizienz von 2015 bis 2022

Abbildung: Entwicklung der CO2-Intensität von 2015 bis 2022

Product Finder

Rüthi (St.Gallen) | 1 minutes reading time

Product Finder

Discover the sheer variety of packaging solutions for the dairy industry with our Product Finder – a world of innovation and sustainability that leaves nothing to be desired.

Our Finder tool provides access to a wide range of advanced packaging options that not only meet the highest quality standards but are also environmentally friendly and resource-efficient. Find the ideal packaging solution tailored to your product requirements, and if you can’t find what you're looking for, feel free to reach out to us personally. We are always striving to set higher packaging standards and to make the impossible, possible.

The countdown begins: Our new website featuring a fresh, modernized corporate identity and a cutting-edge Product Finder is just around the corner!

NAT®Cap: The sustainable Choice.

Rüthi (St.Gallen) | 2 minutes reading time

NAT®Cap: The sustainable Choice – that really works.

Coffee capsules made of plastic or aluminium are very popular and offer end customers very good quality and high convenience in their daily coffee enjoyment. At Säntis, we make every effort to make our plastic capsules as recyclable as possible and to conserve resources as much as possible by keeping their weight to a minimum.

An alternative to recyclable capsules is the compostable capsule. With the composting of the capsule including the coffee, it is also possible to usefully recycle the valuable coffee grounds. This idea is also in line with the EU's PPWR (Packaging and Packaging Waste Directive), which is currently being drafted.

The responsible consumer thus has several alternatives at his disposal, so that he can continue to enjoy his freshly brewed morning coffee from the capsule with a clear conscience.

Did you know that...

...the capsule is only responsible for 2% of the total CO2 footprint when it comes to a cup of coffee?

We are a climate neutral company

Rüthi (St.Gallen) | 5 minutes reading time

We are a climate neutral company.

säntis packaging ag takes climate action.

As one of the first medium-sized companies in the industry, säntis packaging ag has recently been operating as a "climate-neutral certified company" as of 01. August 2022. As so often in its 100-year history, SÄNTIS is once again assuming a pioneering role in this area of expertise.

Despite the complexity of the process, the CO2 balance of the entire company’s value chain was analysed, evaluated, and subsequently optimised alongside ClimatePartner, a company that specializes in climate protection with focus on embedding climate action into corporate activity. The resulting CO2 emissions that cannot (yet) be avoided are offset to the same extent. This means that by supporting a climate protection project through ClimatePartner (whilst meeting clearly defined industry standards) we are able to compensate the remaining emissions to achieve a carbon neutral footprint.

ClimatePartner's climate protection projects are, invariably, always development projects that benefit the local demographic. For example, the SÄNTIS-backed climate protection project promotes the use of renewable energy, in this case wind energy, in north-eastern Brazil. The project is certified according to international standards and is regularly checked by independent third parties - the contribution to CO2 reduction can therefore be clearly measured in the atmosphere.

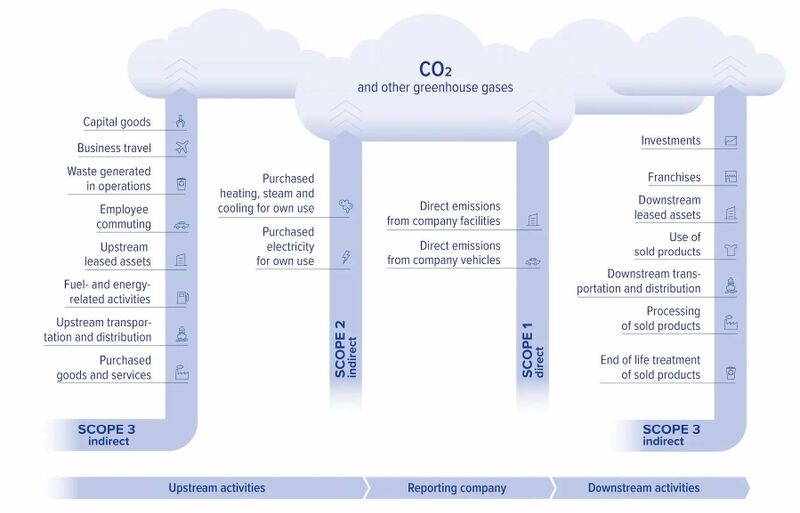

Corporate carbon footprint

An intensive emissions check preceded the official award of the “climate-neutral” rating. All greenhouse gases generated by the company were recorded: from heating to electricity, business trips, employee commuting to office supplies. Together with ClimatePartner, säntis packaging were able to calculate its corporate carbon footprint (CCF).

The assessment according to the internationally recognized GHG Protocol (Greenhouse Gas Protocol) divides a company's emissions into three areas (scopes):

- Scope 1 includes all emissions that are generated directly by the company, such as company-owned systems or vehicle fleets.

- Scope 2 includes those emissions that are caused by purchased energy such as electricity or district heating.

- Scope 3 covers all other emissions that are not subject to direct corporate control (e.g., raw materials, logistics, business trips, employee commuting).

Image: Activities divided by scope. © ClimatePartner

While the company's own emissions are negligible at 0.4%, the indirect greenhouse gases from Scope 3 account for 90% of all CO2 emissions at säntis packaging. This includes all purchased production and consumable materials as well as the end-of-life treatment of sold products in particular.

«Only those who know where most of their CO2 emissions are produced, and how high they are, can react accordingly.»

Management Team, SÄNTIS Group

Circular Economy

Contrary to popular belief, sustainability and plastic are very compatible - and not a contradiction in terms. It is crucial that plastic is not disposed of after a single use, but is re-introduced to the cycle. In accordance with our company's circular economy strategy, we already take the full circularity of our products into close consideration when designing and developing them.

Over the course of the cooperation with ClimatePartner, the ecological footprint of our products were also calculated. At the customer's request, we are subsequently able to offer climate-neutral products. Depending on the origin of the material, these can be specifically designed to be compostable, recyclable and/or bio-circular in order to meet the customer’s individually desired sustainability goal.

Exemplifying sustainability

Sustainability has long been an integral component of Säntis Group’s strategic orientation. In addition to reaching a "climate-neutral company" milestone, the company is making large strides turning ideas into actions.

In accordance with our company philosophy, sustainability efforts have been actively practiced in recent years - as highlights of our previous projects and initiatives show:

- ISCC Plus certification

Since April of this year, the ISCC-PLUS certification, which applies to the entire Säntis Group, guarantees that verifiably sustainable materials are processed in our companies and that bio-circular raw materials are traceable along the entire value chain. - Efficient energy management

As a participant in the "Major Energy Users of the Canton of St. Gallen" project by the Swiss Energy Agency for Industry (EnAW), we pursue a continuous energy-saving plan. With an investment in a 7,000m2 large photovoltaic system as from 2023, 1.6 million kwh of renewable electricity will be generated annually - an important technological step for the sustainable energy supply of the future. This yearly output is equivalent to the electricity supply needed to power over 500 households. As part of our 10-year plan, SÄNTIS has set itself the goal of saving 20% of its current yearly energy consumption. - Reduce emissions, increase efficiency

from 2015 to 2021, the company's own CO2 intensity was reduced from 95% to 34.1%, while an increase in energy efficiency of +10% was achieved in the same period. Since 2013, all members of the Swiss Energy Agency have collectively saved 721,870 tonnes of CO2, the equivalent of approximately 730 million Swiss Francs. - Intelligent construction

All window facades of the SÄNTIS’ office building in Rüthi were equipped with sun-repellent UV film to save on cooling costs during hotter temperatures. A renovation and insulation of the roof and facade at all production plants have significantly reduced overall energy consumption. Other highlights include: the replacement of all air compressors with a state-of-the-art heat recovery system and the installation of a central cooling system with groundwater cooling. - Green electricity

...is used at the subsidiary, Swiss Prime Pack AG.

There is no plan B for our planet

Responsibility for our environment is a self-evident (and now accurately measured) factor in our business model. Sustainable action is considered and applied in every strategic decision. This applies not only to the production process, energy management, responsible and conscious use of resources or the raw materials and processes used, but also includes social responsibility towards our employees, customers, suppliers and other stakeholders.

SÄNTIS Group celebrates 100 years

Rüthi, May 17, 2022 | 5 minutes reading time

SÄNTIS Group celebrates 100 years of

pioneering spirit and uncompromised passion

The “Säntis Battery Factory Johann Göldi” was entered into the commercial register of the Swiss Canton of St. Gallen in 1922. This date marks the beginning of a 100-year company history that would start with the manufacture of batteries to the production of plastic packaging, eventually exporting to an international remit. A century later, "SÄNTIS" is a globally recognised corporate group consisting of three production sites, all located in Eastern Switzerland. According to CEO Bettina Fleisch, the history of the SÄNTIS Group tells the story of passionate entrepreneurs that have been, are and always will be willing to take courageous decisions and to drive change wherever necessary.

On the 10th of September, more than 200 employees, companions, and many well-wishers came together, to duly celebrate 100 years of the company’s existence at its headquarters in Rüthi. Numerous visitors took an eager look behind the scenes at our open factory day and gained a detailed insight into the world of SÄNTIS: from the warehouse boasting a wide range of battery products at our sister company, Säntis Batterie AG, to the state-of-the-art thermoforming lines and enormous injection moulding tools that generate the production of billions of sustainable plastic packaging solutions per year. All those present were fascinated by the activities on display at the company HQ – lingering until the early evening to participate in stimulating discussions, and to celebrate the anniversary accordingly.

Constant reinvention an no fear of change.

For the owner Bettina Fleisch, the 100 years of leadership portrays a story of constant proactive change. ‘’Only those who adapt to changes and act with foresight can lead a company successfully in the long term. You have to keep reinventing yourself." This pioneering spirit has been a cornerstone of SÄNTIS to this present day.

In the early 1950s, Hans Göldi the son of the company's founder recognized at the time that this relatively unfamiliar “plastic" would serve as an ideal protective function for various battery components. Consequently, he would install an in-house injection moulding department - thus laying the foundation for an additional company specialisation, plastics processing.

«Only those who adapt to changes and act with foresight can lead a company successfully in the long term. You have to keep reinventing yourself.»

Bettina Fleisch, Owner & CEO Säntis+ Group

With innovative products on the path to success.

As a "plastics pioneer", SÄNTIS would go on to be at the forefront of many innovative packaging solutions. The big breakthrough came with the production of the first yoghurt cups made from polystyrene via an injection moulding process. Further milestones followed such as the first plastic bottles made from polyethylene and PVC using extrusion blow moulding. The legendary red Swiss “Handy” bottle was one of the first assembly line containers, the first PET bottles on the Swiss market manufactured by stretch blow moulding technology as well as the production of the company’s very own extruded film rolls for the thermoforming plant, both in mono-layer as well as multi-layer variants. Professional «tinkering» has always been deeply anchored in the company DNA.

Then came the coffee capsule. As an already established specialist in barrier packaging, SÄNTIS played a key role in defining the capsule market together with the "father of the coffee capsule". The first "SÄNTIS capsule" was made from PP-EVOH in 1991. The courageous decision paid off. Today, several billion capsules in various shapes for a wide variety of capsule systems are fired off the assembly line in Rüthi every year.

From manufacturer to retailer: from direct selling of batteries to direct sales with a firm multi-channel strategy.

The battery division was permanently closed in 2005 for strategic reasons. Since then, "Säntis Batterie AG" (formerly Säntis J. Göldi AG), which has now been renamed and transformed for the third time, has specialised in the sale of high-quality batteries and lubricants throughout Switzerland as a separately managed sister company to säntis packaging. Today, a workforce of 15 motivated employees are proud of their diversified online shop with a product portfolio consisting of over 3,000 items, servicing more than 5,000 satisfied customers every day throughout Switzerland. To mark the company’s 100th birthday, the business underwent a modern rebranding, because "standing-still is the equivalent to going backwards". Junior boss and marketing manager Benjamin Fleisch, wants to keep the company’s batteries fully charged and well-equipped to take on the 4th generation of leadership on the road to success.

Staying one step ahead, going beyond limits.

Innovative ideas, a high level of quality awareness and a keen entrepreneurial vision, continue to be a recipe for success at säntis packaging. A cooperation with Canadian plastic packaging specialist "Hoffmann Plastics" from 2019 would eventually strengthen the group as a collective force – jointly growing in international markets whilst taking two plastic packaging pioneers from different continents to eye-level. SÄNTIS would then further secure its supremacy in the Swiss market with the acquisition of "Swiss Prime Pack AG", a longstanding packaging specialist well positioned in the dairy industry. Under the newly formed umbrella brand “SÄNTIS – Swiss Prime Packaging”, the company group is pursuing the ambitious goal of becoming one of the three largest packaging manufacturers in Switzerland.

And just in time for the 100th anniversary, SÄNTIS is once again leading the way when it comes to sustainability: as from August 2022, säntis packaging ag is a climate-neutral company. This means that the company motto ‘’Sustainability is not an option. It's a responsibility" is actively implemented at a time where the company aims to further their important contribution in reducing CO2 emissions.

Predicting the future by self-creating it.

The effects of global climate change, however, is only part of the major challenges that the company, like many others, are currently facing. Exploding energy prices, shortages of raw materials and a dearth of skilled workers, have been keenly felt at SÄNTIS. Despite this “we are well positioned, we have a motivated and ambitious team that enables us to take on these challenging tasks,” our passionate entrepreneurial spirit looks ahead to the next few years with confidence and optimism.

ISCC PLUS certification for säntis packaging ag

Rüthi, May 17, 2022 | 5 minutes reading time

ISCC PLUS certification for säntis packaging ag

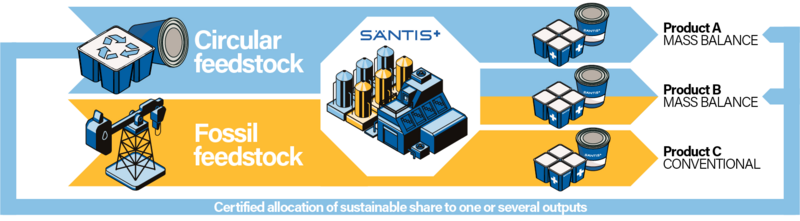

All locations of the Säntis Group (säntis packaging ag and SwissPrimePack AG) have successfully obtained their individual ISCC PLUS certification as per April 2022. Thanks to the «International Sustainability and Carbon Certification», companies are now officially authorised to process chemically recycled and/or bio-circular materials and to associate the corresponding ISCC logo to their packaging. The ISCC PLUS is a by audit independently verified label that guarantees the usage and traceability of sustainable materials for circular packaging.

As the company announces, this is an important step towards further developing and realising the company's circular economy strategy - breaking new grounds both with raw material suppliers as well as customers whilst achieving more sustainability and transparency along the entirety of the supply chain.

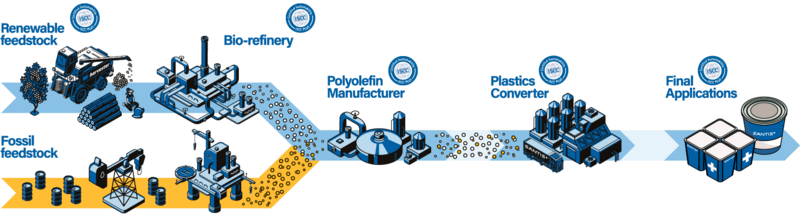

With ISCC PLUS, the globally recognised management system was expanded to include further aspects relevant to the circular economy, based on mass balance certifications. The aim of the certification is to ensure the traceability of bio-circular raw materials along the entire value chain - from raw material suppliers in the chemical industry to packaging converters, through to food processors and brand owners.

ISCC PLUS is also dedicated to stopping deforestation and to protecting areas with high biodiversity and high carbon stocks.

Transparent traceability: counteracting material shortages.

Moving forward with the ISCC PLUS certification, säntis packaging aims to integrate a gradually increasing proportion of renewable resources in the production of their plastic packaging, thus aspiring to achieve substantial savings of primary resources in the future.

The globally applicable, chain of custody certification system covers all sustainable raw materials, including agricultural and forestry biomass, biogenic waste and residues as well as recycled and renewable raw materials. This aforementioned bio-circular raw material group is also called «2. Generation Feedstock" and represents the recycling-oriented alternative to plastics of fossil origin within the framework of the ISCC.

Based on the mass balance principle, a proportion of fossil resources is replaced by sustainable biomass right at the beginning of the production process. The added share of renewable raw materials is assigned to the new product.

«Mass balancing enables us to transparently control bio-circular materials and products. The aim is not only to maintain the cycle, but also to continuously optimize and increase the quantity and sustainability of the raw materials used.»

Michael Matiz, Head of SCM and QM at säntis packaging

Image: Sustainable material cycles for more circularity. © säntis packaging ag 2022

Revolutionising plastic with chemical recycling -

used plastic becomes reusable plastic.

An important aspect of the ISCC PLUS certification is the goal of bringing chemically recycled materials back into circulation and therefore providing them with a new, re-allocated life-cycle.

The starting point for the production of certified, circular PP polymer is the chemical recycling of mixed plastic waste or scrap that is difficult to mechanically recycle and is therefore mostly either incinerated at the end of its life cycle or landfilled.

The resulting recycled PP polymer has undergone ISCC PLUS certification and is an authenticated and verified product that can be traced at every step of its process – from its sourcing and manufacture, through to its conversion into packaging and ending in its final product application, before being reintroduced to its newly allocated life cycle. The bio-circular PP shares the identical characteristics as its corresponding (fossil) virgin material version, meaning furthermore that quality and hygiene standards as well as food safety are not affected in any way.

«For our customers and their consumers, this means full transparency along the value chain. All parties can be confident that these market products are of bio-based origin and are made from renewable materials.»

Marco Reiss, Head of Sales, Division Barrier Packaging at säntis packaging

The ISCC-PLUS certification process is significantly more complex than the ISO certification, since all company locations must be certified individually. Not only is the plant headquartered in Rüthi (St. Gallen) ISCC-Plus certified, but also both production sites of the subsidiary SwissPrimePack AG in Altstätten and Niederuzwil.

Image: The Mass Balance Approach © säntis packaging ag 2022

What changes in and around my packaging when using bio-circular raw materials?

- Food safety still guaranteed

- Decoration still possible, provided the packaging remains mono-material based as a unit

- Same properties as fossil material (drop-in solution)

- Quality, performance, design and functionality of the packaging remain identical

- ISCC Plus certified; based on mass balance approach

- Packaging solution consists of higher share of recycled material(s)

- Highly reduced/optimised CO2 footprint

The simple conclusion: More sustainability, and unchanged quality, safety and hygiene standards.

Less CO2, more ecological gain.

The use of recycled and/or bio-based materials ensures a significant emission reduction of harmful CO2.

Polyolefins, which are obtained entirely from waste and residue streams, have the same material properties as virgin material, but are processed into usable raw materials with a significantly lower carbon footprint. The CO2 saving amounts to approx. 2.5kg CO2eq (CO2 equivalent) for every kilogram of polymer that is produced, which in turn means a concrete saving of approx. 120% compared to fossil polypropylene (PP). The depletion of fossil resources can also be reduced by up to around 85%.

In long-term partnerships, säntis packaging continues to develop and pursue several sustainable ideas with various global players in the chemical industry, with the clear goal of applying these formulations to innovative food packaging – of course without compromising quality, performance or migration and food safety standards. At present, several projects engaged with the processing of recycled and recyclable materials such as rPP, rPET or rPS i.e., post-consumer waste are underway at säntis packaging and will be market ready very soon.

The company’s highest maxim for the future still remains:

«Sustainability is not an option. It's a responsibility.»

The entire workforce at säntis packaging ag

Young Tec Fun Days 2021 at säntis packaging ag in Rüthi

Young Tec Fun Days 2021 at säntis packaging ag in Rüthi

Earlier this year, 6 children aged 10 years young spent two working days at säntis packaging in order to gain their first experience in various technical professions.

Day 1 started with an interesting video explaining how granulates and plastic parts are manufactured. In the company's own laboratory, the kids were then allowed to work on small jobs on the CAD and design their own smartphone holder using our in-house 3D printer.

Equipped with original apprentice clothing and safety shoes, on day 2 the kids went on to try their hand at an injection moulding machine and subsequently take several quality measuring points of the parts they had produced. The corresponding tool then had to be revised and serviced by the young candidates in the tool shop.

Despite their young age, the children showed an unexpectedly high level of interest in all the processes and were enormously committed and participated. For us a clear sign that young people cannot be brought into contact with the fascinating world of technology early enough. The girls were no less eager than their male counterparts, by the way. Bravo!

For us, this pilot test was a very pleasant experience that we would gladly be open to repeat at any time in the future!