Quality and Precision

„Quality means doing it right when no one is looking.“ – Henry Ford

Quality Management

With active quality management in accordance with ISO 9001:2015 and the extensive know-how of our employees, we guarantee quality at the highest level.

In addition to various inline inspection instruments, a competent team in all areas of production and final inspection also ensures the highest possible security level offline.

We work according to international BRC/IOP standards. We thus also set standards in strict hygiene conditions in and around our entire production processes.

Organisational control mechanisms ensure reproducibility, traceability, action measures and the ongoing analysis and optimisation of all links in the consumer chain.

In addition, säntis packaging carries out regular ATP tests (hygiene tests) at its facilities and is audited and checked at regular intervals by external, independent certification bodies.

Offline Quality Procedures

High-precision plastic parts require highly qualified measuring technology.

In recent years, we at säntis packaging have raised thermoforming technology to a level that allows us to achieve manufacturing tolerances similar to those of injection moulding. For example, we guarantee precision in the hundredths range in the manufacture of plastic capsules.

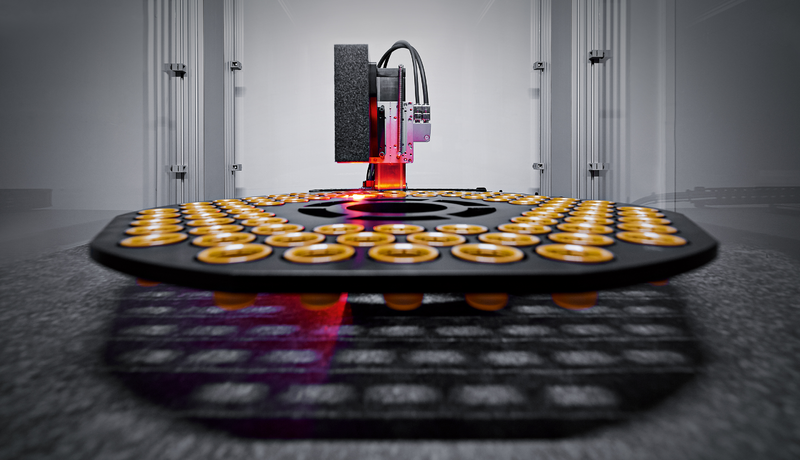

Using our OCT measuring system, we test during the process with absolute precision and maximum measuring speed. Especially in the field of manufacturing capsule systems, OCT technology is used to determine various geometric properties on the 3D component, such as the outer and inner diameter, wall thickness or general mass at a defined height.

The measurements are made with an accuracy of +/- 1 µm.

Inline Quality Procedures

On our production facilities, we measure and test for various deviations with different optical measuring instruments during the ongoing production processes.

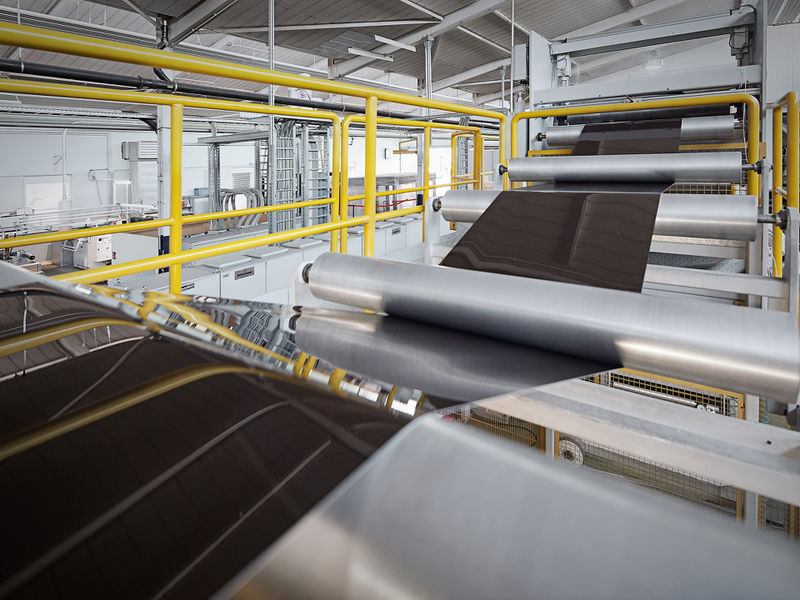

Sheet Extrusion:

- camera system in reflection and transmission for detection of impurities and imperfections on the sheet surface

- integrated ultrasonic measuring device in the low µ-range

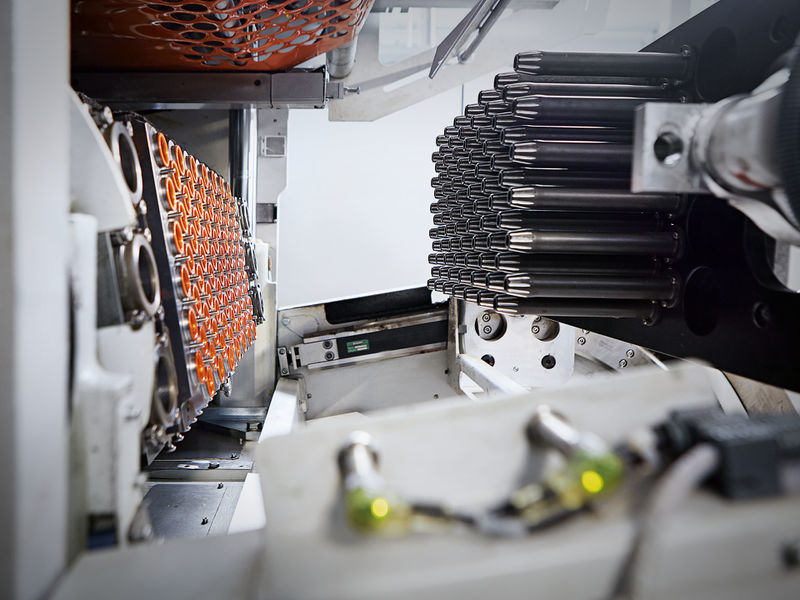

Camera System in Injection Moulding:

- parallelism or flatness/planity of the injection-moulded part

- positioning or centring of the IML

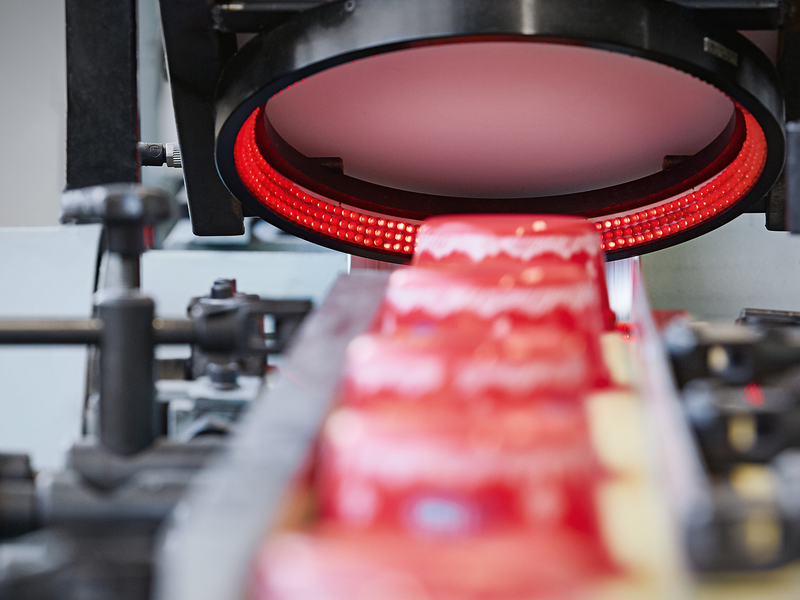

Camera System in Thermoforming:

- diameter, position and roundness of the punched hole

- measurement of the outer diameter of capsules, cups, etc.

All camera systems used in the machine park are equipped with 4k resolution.

Laboratory

Our development department processes and accompanies up to 1,000 tests and samples annually.

We measure, test, control and develop a wide variety of components in a modern laboratory. With precise instruments, we measure material specifications, colour references, layer structures, wall distributions, thermal deformability and much more.

Warehouse & Logistics

säntis packaging operates with a functional logistics system in which an automated warehouse with a pallet conveyor system eliminates the interface between production and goods export/delivery in a cost- and above all time-efficient manner. In addition, mobile data acquisition via MDE hand-held devices ensures batch-controlled warehouse management of our FIFO deliveries, which contributes significantly to our internal process optimisation.

Werkzeugbau

Tool Construction with CAD

In an internal tool and product design department, our experts construct customer-specific solutions, creatively and functionally. Using CAD modelling, our designers transfer the technical data of the packaging requirement to sample or subsequently to series tools.

We accompany you professionally and comprehensively from the idea to the realisation and guarantee:

- cost innovation

- quality

- competence: experience & expertise

- product innovation: aesthetics & attractiveness

- product functionality: uniqueness & handling

- quick time to market: high flexibility and rapid implementation

Tools: Construction, Revision and Optimisation

In the sense of a well-founded and rapid development process, we design and build prototype tools in-house. Depending on the requirement profile, we offer simple and cost-effective application solutions up to complex multi-cavity moulds.

Of course, all maintenance work is computer-assisted and proactively monitored by us.

We have decades of know-how in the manufacture, maintenance and optimisation of tools from all areas of production and production technologies we cover.